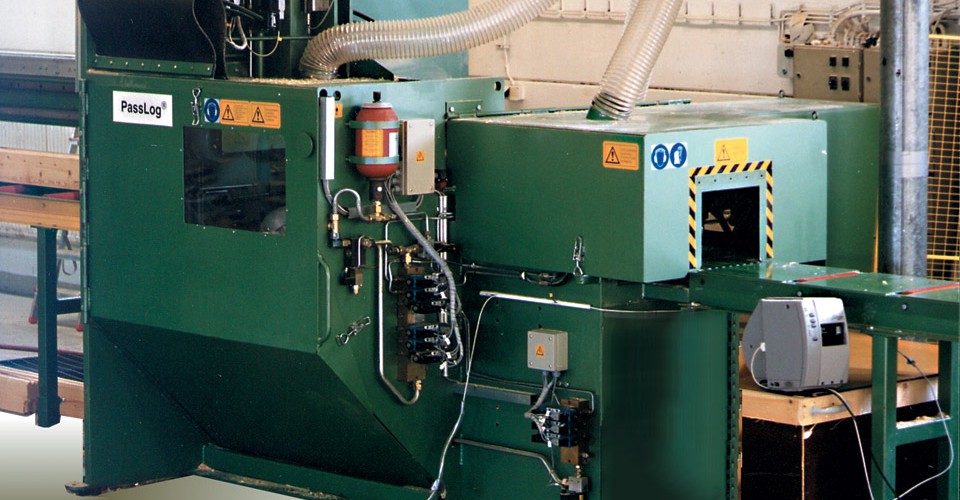

Log processing machinery

PassLog®

PassLog®–log processing production line ensures that timber processing is done efficiently by using one feed.

Corner joints:

- Light wall groove

- saddle corner joint

- floor processing

- straight, asymmetric joint

- form closed non projected corner joint with a tongue and groove

- T-joint driven through the side of the log

- Possibility to make joints for unequal sized walls

CAD-drawing is programmed to the computer where the program counts the perfect usage of each log. The logs that are being fed can be regular sized, for example 6 m or various different lengths. Logs are used efficiently as it is possible, the amount of waste is minimal. Pushing optimization end is 12 meters long and its position accuracy is 0,1 mm.

The machine can be used to manufacture up to two or three houses simultaneously. The machine makes automatic sawing, gaps, drilling and all the required machining.

Round-, plane- and lamella log processing

Corner joints can be made with PassLog®-production lines to plane- and round logs. Drilling is done with four completely independent drilling units, which can drill through and half way of the log. Production line takes care of sawing the gaps (window holes to the wall) and for the end bevel sawing.

The log is being cut at the last phase by the production machine so it can process even very short logs.

Control system

- PC-based

- log measuring and optimizing

- suitability for CAD-programs (HirsiCAD)

- adjustment- and control features

- settings saved by log diameters

- Sticker printing

PassLog®–customers:

http://www.kuusamohirsitalot.fi (Kuusamon Hirsitalot Oy)

http://www.honkatalot.fi (Honkatalot Oy)

AS Kartas (Turkki)